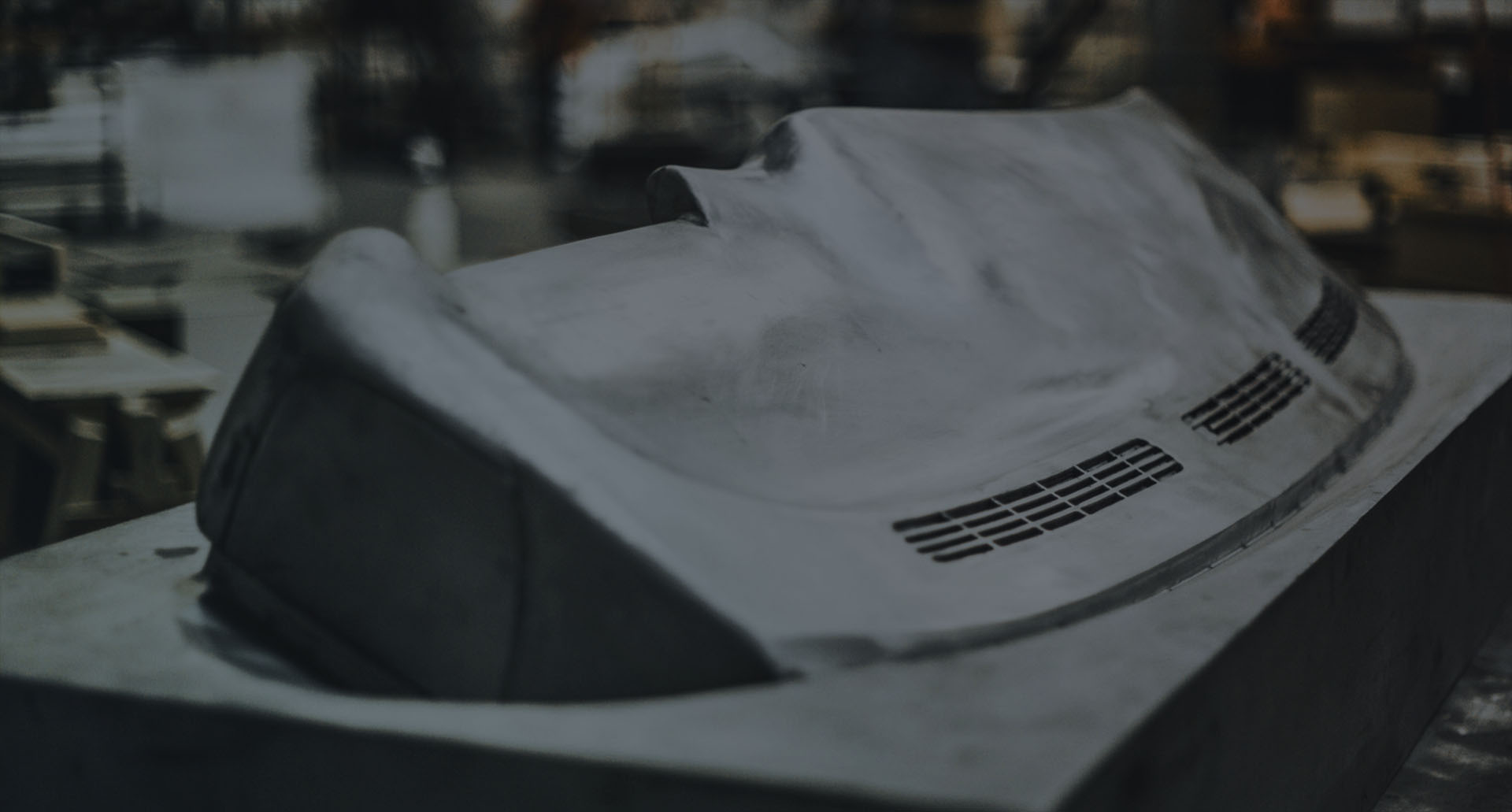

The strength and structure of your vacuum formed parts are directly affected by the mold design and mold materials. Our in house tooling and trim fixture capability allows us to offer a wide range of cost effective tooling solutions.

Fiber Pad provides expert tooling consultation and recommendation to fit the exact needs and budget for your project. We cater to: one offs, prototypes, short run production, low volume production and high volume production.

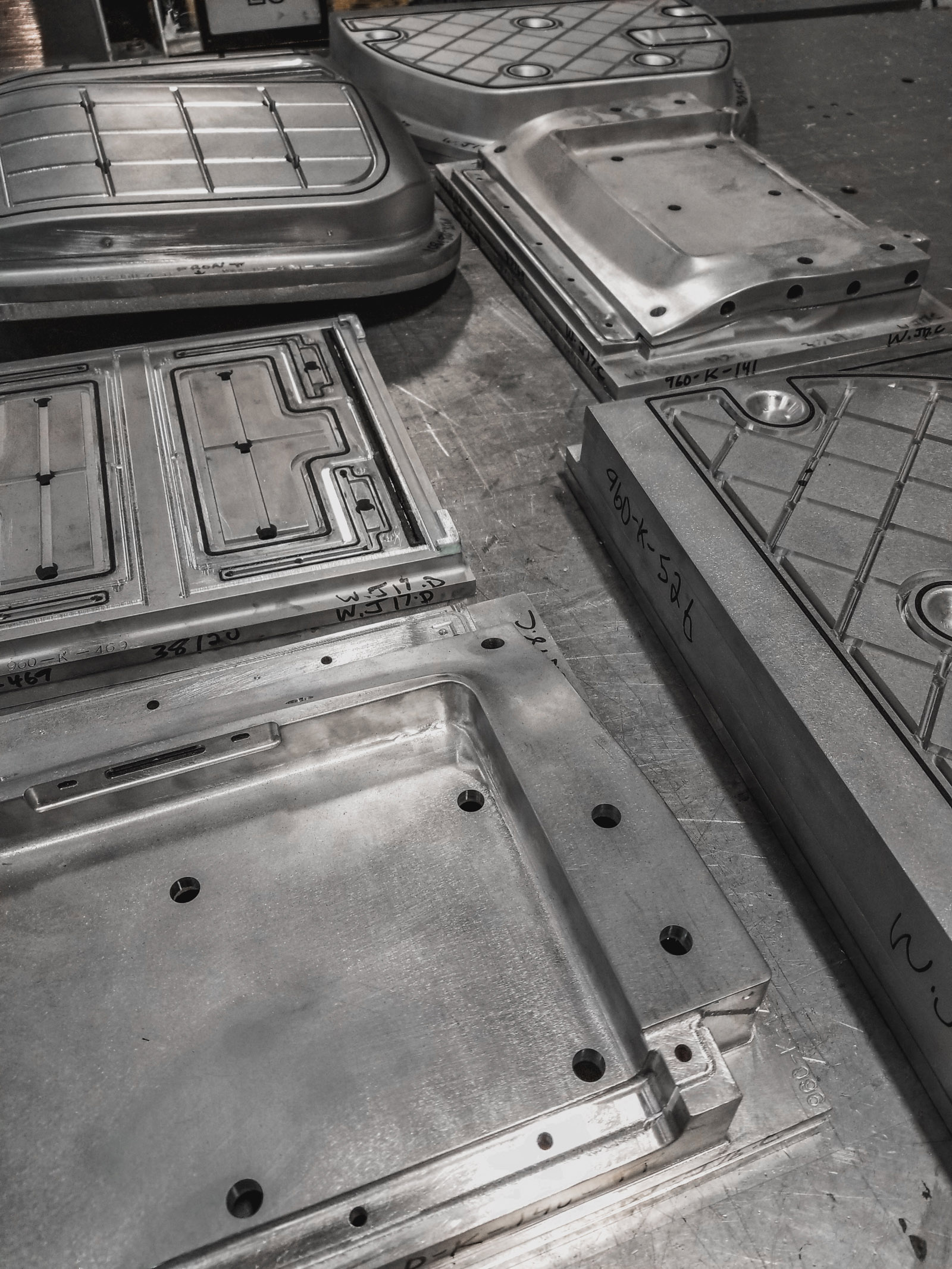

Fiber Pad expertly designs your molds to maximize plastic sheet usage, giving you the maximum amount of components per sheet of plastic.

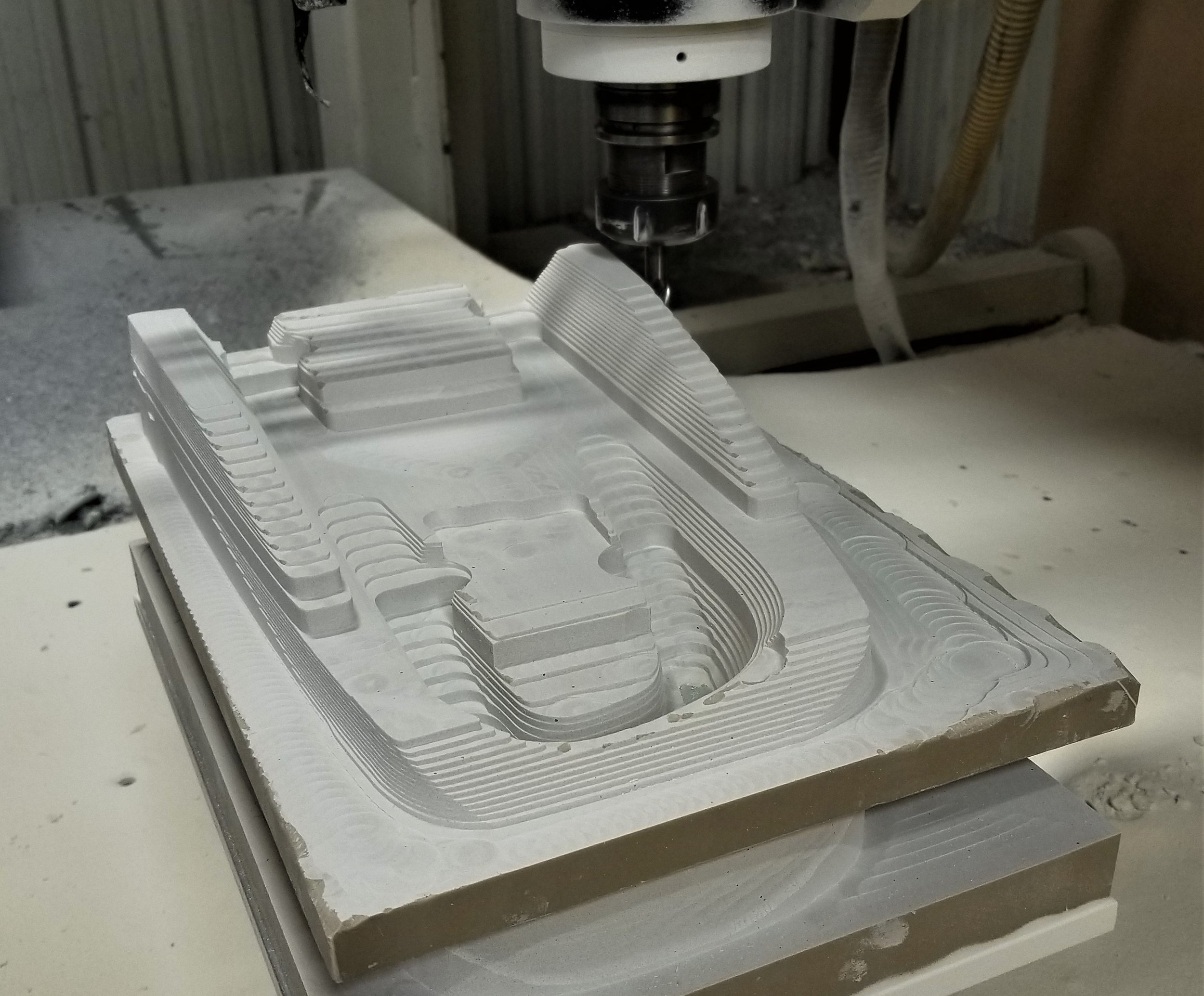

Thermoforming exerts very low stresses on the molding surface, therefore, less expensive softer mold materials can be used such as wood, epoxy, and aluminum.

Softer mold materials mean faster cut times, which means shorter lead times to get your products to market faster.

Thermoforming tooling is significantly less expensive than injection molding tooling.

Typically the larger the component the more economical the tooling cost becomes compared to all other plastic molding services

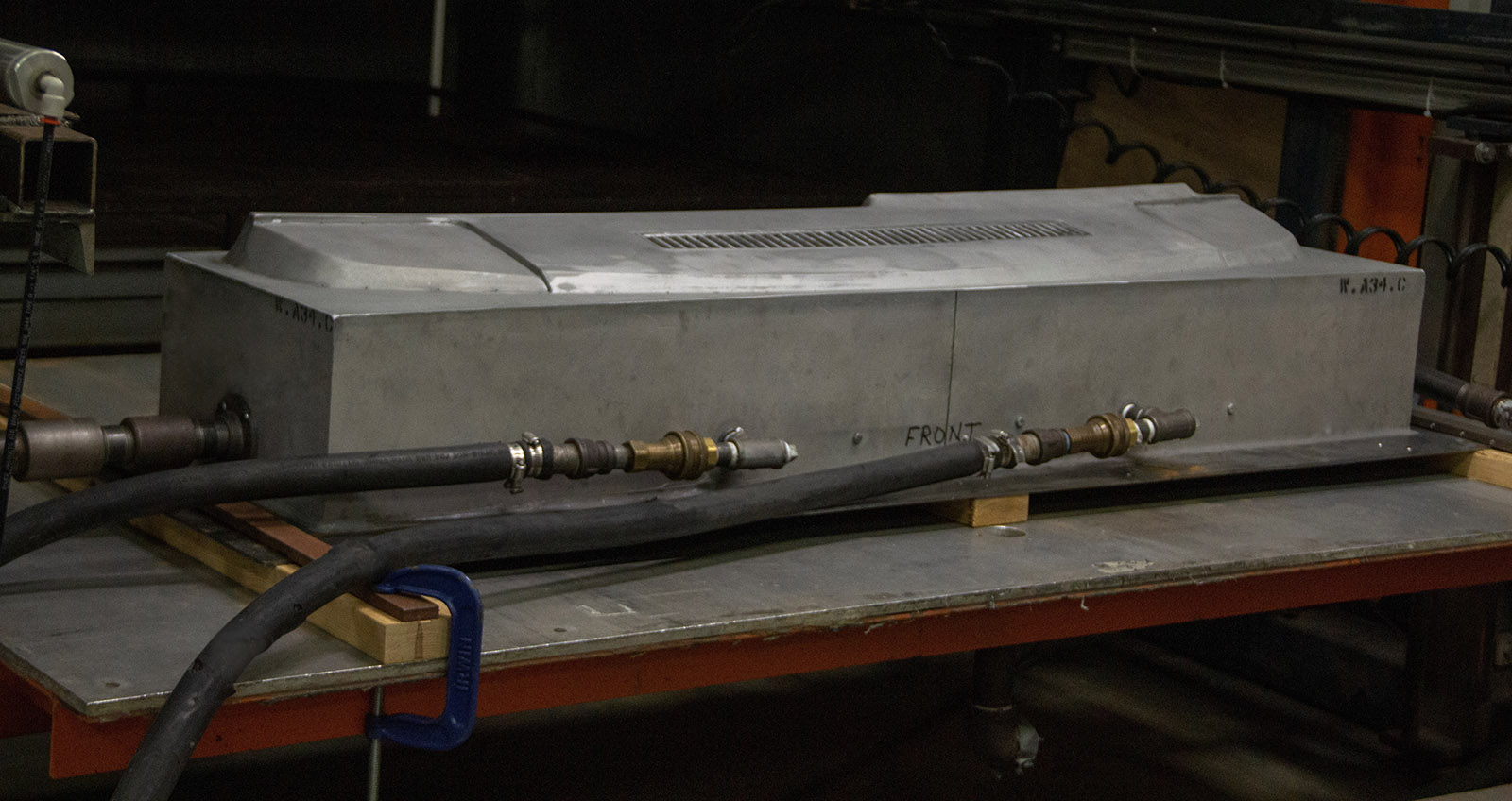

We offer: temperature controlled molds, cast aluminum molds, machined aluminum molds, epoxy molds, and wood molds.